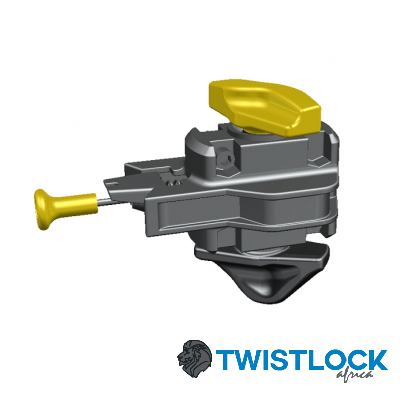

The semi-automatic twistlock – single toggle is load rated for lifting purposes. Allows you to top lift double stacked empty containers. Semi-automatic Twist Locks can be pre-loaded and will shut automatically when a container is placed on them. These twist locks are also rated and marked for a 10T lifting capacity.

Material: Heat Treatable Steel

Finish: Hot Dip Galvanised

Minimum breaking loads tension 500 kN / shear 420 kN

Dual function for manual and semi-automatic mode

This unit is currently widely used by the shipping industry to secure containers on ships.

The semi-automatic twistlock – single toggle offers automatic locking when the top container is landed on the bottom container. This product offers the user a safer option to stack containers long term as no access is required to engage each unit, offering a faster and more cost-effective alternative. It is intradiscally safe in that its fail-safe position is in the locked position.

Numerous variants available in the market.

To install (in preparation for mounting the container):

The unit is normally inserted into the bottom corner casting by inserting the YELLOW tab into the corner casting and twisting the body so that the twistlock body engages with the hole in the corner casting. The YELLOW tab will spring into the locked position.

Once all 4 twistlocks are installed, the container can be lifted and then lowered into position. The 4 twistlocks will automatically engage and lock into the top corner castings of the bottom container.

To remove the top container, the pull tab on each twistlock must be pulled and locked into the locked position. The top container can be lifted off the bottom container. Once the container has been lowered near to ground level, the twistlocks can be removed by turning the bottom (Silver) arrowhead until the twistlock falls out of the corner casting.

Features

- Material: Cast and Forged Steel

- Surface Treatment: Hot dipped galvanised

- Upper cone marked yellow for quick orientation

- Weight 5.5 Kg

- B.L tension: 500kN

- B.L shear: 420kN

- B.L compression: 2000 kN

- Normally bought in sets of 4

- Available in varying designs.